Reduced railcar weight lessens carbon emissions; Improved design extends useful life

Three of America's leading industrial and transportation companies – United States Steel Corporation (NYSE: X), Norfolk Southern Corporation (NYSE: NSC) and The Greenbrier Companies, Inc. (NYSE: GBX) – today jointly announced a new, more sustainable steel gondola railcar. Using an innovative formula for high-strength, lighter-weight steel developed by U. S. Steel, each gondola’s unloaded weight is reduced by up to 15,000 pounds. Gondola railcars transport loose bulk material such as metal scraps, coils, wood chips, steel slabs, and ore. Norfolk Southern will initially acquire 800 of the Greenbrier engineered gondolas.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20211209005320/en/

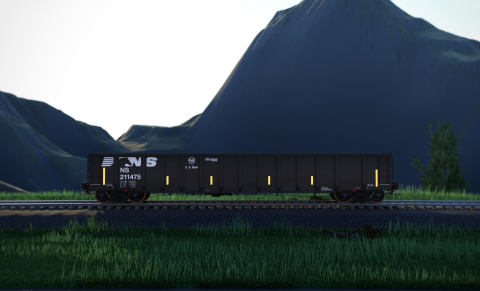

High-strength steel gondola rendering. (Photo: Business Wire)

The partnership between supplier, builder, and end-user is rooted in the recognition that North America's aging gondola fleet will soon require substantial replacement with a more sustainable design. U. S. Steel's materials innovation, Norfolk Southern's commitment to sustainable freight transportation, and Greenbrier's deep engineering capability have led to a stronger, lighter, and more energy-efficient product for the freight rail industry. U. S. Steel is a leader in designing advanced, lightweight and high-strength steel solutions for the automotive industry. It identified the interconnections between steel advancements for automobiles and adapted these to the rail industry.

Features of the newly designed gondolas provide several benefits:

- Extended Lifecycle: The new steel is twice as strong as traditional steel used in the railcar manufacturing process, potentially extending the useful life of each gondola to 50 years. A stronger external finish also strengthens the railcar body, lowering maintenance costs.

- Increased Sustainability: The new gondola is more energy-efficient, both during production and in use. The steel fabrication process requires less time, leading to improved energy efficiency due to less material being used. The lower weight decreases the fuel needed by locomotives hauling the railcars, reducing energy usage and lowering emissions.

- Greater Freight Capacity: Enhancements to the gondola design also afford greater freight capacity. The high-strength steel requires less structural reinforcement, simplifying the manufacturing process and allowing more total cargo space in each railcar.

“This remarkable collaboration with our partners at Norfolk Southern and Greenbrier is helping realize the full potential of U. S. Steel’s continued product innovations as sustainable solutions for the steel and transportation industries,” said U. S. Steel President and CEO David B. Burritt. “We’ve often said that together we can do anything! This joint initiative proves that point with an innovative railcar that is stronger, lighter and more capable, with the planet being the ultimate beneficiary.”

“The use of lightweight, high-strength steel is a real revolution for railcars. Not only will each gondola carry more material, they will do so by using less energy, making our operations, and our customer’s operations, even more environmentally friendly,” said James A. Squires, chairman and CEO of Norfolk Southern. “The advancements made by Norfolk Southern, U.S. Steel, and Greenbrier on these gondolas can be applied to other car types, ensuring that this sustainable innovation continues well into the future. Further, once these new gondolas are in service, we plan to recycle the previous models.”

“The work done by U. S. Steel, Norfolk Southern and Greenbrier promises significant benefits to all three companies and the freight transportation industry as a whole. The three partners on this next-generation transportation equipment have deep roots in industrial America. Together, we are leading the way to a net-zero carbon economy. I look forward to our continued partnership,” said William A. Furman, Greenbrier Chairman and CEO.

Moving freight by rail is the most environmentally friendly mode of surface transport, with the average U. S. railroad moving one ton of freight 470 miles per gallon of fuel. The high-strength steel gondola aims to further improve this performance for railroads. Learn more about the high-strength steel collaboration at go.gbrx.com/gondola.

About U. S. Steel

Founded in 1901, United States Steel Corporation is a leading steel producer. With an unwavering focus on safety, the company’s customer-centric Best for AllSM strategy is advancing a more secure, sustainable future for U. S. Steel and its stakeholders. With a renewed emphasis on innovation, U. S. Steel serves the automotive, construction, appliance, energy, containers, and packaging industries with high value-added steel products such as U. S. Steel’s proprietary XG3™ advanced high-strength steel. The company also maintains competitively advantaged iron ore production and has an annual raw steelmaking capability of 26.2 million net tons. U. S. Steel is headquartered in Pittsburgh, Pennsylvania, with world-class operations across the United States and in Central Europe. For more information, please visit www.ussteel.com.

About Norfolk Southern

Norfolk Southern Corporation (NYSE: NSC) is one of the nation's premier transportation companies, moving the goods and materials that drive the U.S. economy. Norfolk Southern connects customers to markets and communities to economic opportunity, with safe, reliable, and cost-effective shipping solutions. The company's service area includes 22 states and the District of Columbia, every major container port in the eastern United States, and a majority of the U.S. population and manufacturing base.

About Greenbrier

Greenbrier, headquartered in Lake Oswego, Oregon, is a leading international supplier of equipment and services to global freight transportation markets. Through wholly-owned subsidiaries and joint ventures, Greenbrier designs, builds and markets freight railcars and marine barges in North America, Europe and Brazil. We are a leading provider of freight railcar wheel services, parts, maintenance and retrofitting services in North America through our rail services business unit. Greenbrier manages 444,000 railcars and offers railcar management, regulatory compliance services and leasing services to railroads and other railcars owners in North America. GBX Leasing (GBXL) is a special purpose subsidiary that owns and manages a portfolio of leased railcars that originate primarily from Greenbrier's manufacturing operations. As of September 30, 2021, GBXL and Greenbrier own a lease fleet of nearly 12,500 railcars. Learn more about Greenbrier at www.gbrx.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211209005320/en/

Contacts

John O. Ambler

Vice President

Corporate Communications

T – (412) 433-2407

E – joambler@uss.com